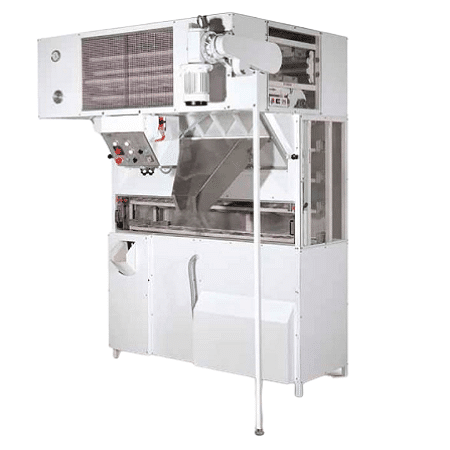

Esmach Automatic Intermediate Proofer ECP

Intermediate proofer, part of the automatized line. The line consists of Esmach Automatic Divider SP1D/E and Esmach FE Bread Loaf Moulder. The setup of these three machines will speed up your production and ease the everyday work process. After the dough is divided and it’s slightly beaten up, the proofer allows it to rest for a few minutes. The proofing time is between 3- 6 minutes. Then the dough continues to moulder and slowly becomes a legit bread. Support structures and covers are made from painted stainless steel. Resting dough pockets are made from nylon mesh and sit in steel tubing. The machine is able to process dough pieces from 200 to 1200 grams. Maximum output is 1200 pieces per hour.Automated bread production

Give it a few minutes after dividing and rounding, and your future bread will be elevated to a new height

Germicidal lamps on standard models to keep the proofer food-safe

Part of automatic bread-making machine, to speed the process

Quality materials, reliable components, and precise engineering ensure long working life

Gives you the opportunity to pick the right for you

Weekdays: 8:30 - 5:00 PST

Weekends: Closed

EM Bakery Equipment USA Inc.

6731 Baymeadow Dr.

Glen Burnie, MD

21061

For Service/Support Contact:

Website by Virtual Roots & curious projects