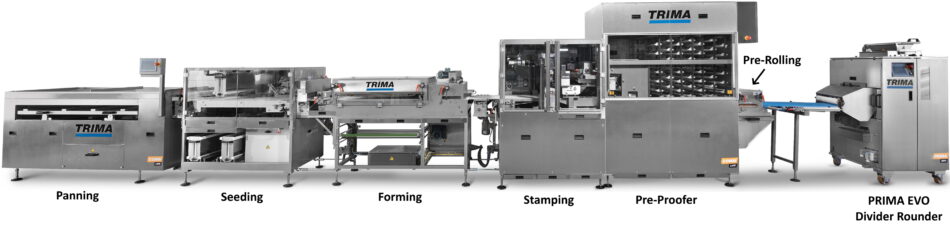

Trima Factory Bun Production System – CombiLine (4-8 lines)

The TRIMA CombiLine is designed to automatically receive dough from a TRIMA Automatic Bun Divider Rounder: KE / PRIMA EVO, then proof and mold/sheet/stamp your product. The systems are modular and can be configured to suit any requirement. Designed for quick and easy operation. Hourly output between 4,000 to 7,000 pieces+ (depending on the # of rows you have chosen to run). Various types of products can run through the same system. The CombiLine is a modular, fully automatic bread roll line operated by a touch screen and carefully engineered to work with all types of dough (wheat, mixed grain, rye, etc.). It produces high-quality products: round, stamped, oval, long-rolled, flattened, cut and seeded, etc. Produce Kaiser rolls, finger rolls, hot dogs, hamburger buns, and dinner rolls (with or without seeding), all in the same line. You decide what to include depending on your available space, product requirements, and budget. The production line can be easily expanded in case your future requirements change.Factory Line Bun Production System

Tailor-made systems for small baked items. Modular construction that can be configured to suit your requirements

Max production with one operator is 7,200 pieces per hour

Built in flexibility to run multiple different products on the same equipment

Stainless steel manufacturing and thoughtful design to enable simple and hygienic cleaning. Automatic cleansing of proofing baskets

Design and automate your production line from start to finish

Maximum capacity: 4 lines– 4800 pieces per hour, 5 lines– 6000 pieces per hour, 6 lines– 7200 pieces per hour, or 8 lines Safety: Emergency button Maintenance: Easy on maintenance Control panels: Yes, touchscreen Programs: Yes, can save programs

Divider Rounder Pre-Rolling Unit Pre-Proofer Unit Stamping Unit Forming Unit Seeding Unit Panning Unit See part of this line for mess-free seed application, TRIMA Seed station.Customizable features:

Different Modules to Add / Choose Between

Troubleshooting? Want to learn more?