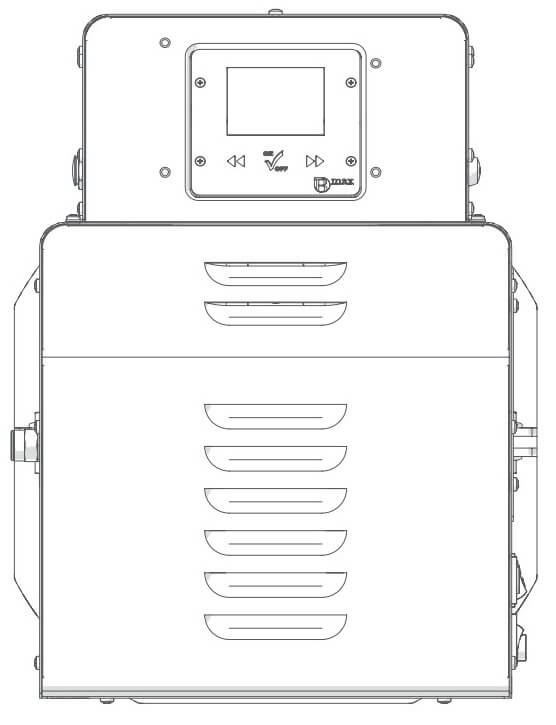

Bassanina Steam Pipes Deck Oven TUBIX

This oven is designed to be the long-term backbone of exceptional artisan product production. Built and assembled at your location, this large deck oven will give you high levels of production and extraordinary control over your bake, uncompromised by its greater size. This oven offers versatility and heat flexibility, enabling rapid temperature adjustment and allowing you to bake your best products (bread, cakes, pizza…) The oven can be controlled via your cell phone. Do you know what it means? Sleeping at night and baking during the day. Revolutionary invent! The oven comes with four overlapping baking chambers, each with independent high-yield steam control, lighting, and a baking deck made of high-performance food-safe cement. First and foremost is its low-cost and extremely powerful heating system: a dense network of closed-circuit pipes in which steam circulates. This oven guarantees constant, optimal heat distribution and extraordinary temperature stability even while loading and unloading your product. The result is a world-class deep bake with strong oven springs, strong crust development and a longer shelf-life. Each deck is designed to work with a custom conveyor belt loader, allowing you to quickly load and unload baked goods with different models of loaders available. Each deck’s tempered crystal glass and steel doors are balanced for fast opening and closing. They can easily be removed for cleaning. The ultimate long-term low operating-cost deck oven. The on-site assembly includes pouring concrete, masonry base, and concrete walls covering the steam pipes. This provides the ultimate level of insulation and radiating heat capacity to deliver long-lasting, stable high heat with minimal thermal loss and utility wastage. The oven build is customizable to your production space. Different sizes and models range from 3-4 decks, with 2-4 doors per deck and three different depths. Custom configurations are also available with side steamers and oversized doors. The standard burner in this oven can be designed to accommodate diesel, propane, or natural gas. OPTIONAL: Add a wood furnace to burn various wood products or a pellet burner and tank/auger system.The Artisanal Powerhouse-production

The ultimate in artisanal quality, low-cost operation and maintenance, and high production

An absolutely uniform amount of heat in every part of the baking chamber at a low cost to operate

Create your best bake: bread that is more developed, shinier, and keeps its look and aroma longer

The oven is designed, built and tested to perform continuous, uninterrupted baking cycles 24 hours a day

Stainless steel throughout, steam pipes without welding and individually inspected. Poured concrete and masonry base and walls

Fuel Source: Gas, propane, wood, wooden pellets Electrical: 3-phase 208 V (compatible with 220 V) 60 Hz, 1-phase 208 V (compatible with 220 V) Optional Shipping weight: 6181 kg (13600 lb)- 11600 kg (25574 lb) Steam: Yes Baking surface: Stone hearth Baking area: 7.9 m2– 23.8 m2 depending on model Temperature Range: Max 300°C (572°F) Even baking: Yes Air movement: Natural Convection Control panel: Electromechanical or digital panel Modularity: No Loader: Yes, integrated belt loader Maintenance: Low maintenance and easy oven cleaning features Safety: Safety thermostat, emergency button, steam exhaust, auto shut off, barometric damper, heating changer

This oven allows you to control steam independently for each baking chamber. In baking, a large quantity of instant steam is needed to optimize the baking of the crust, which gives it a shiny crust, avoiding dehydration problems and bubbles formation. Steam is what maintains the dough’s skin elasticity, allowing the bread to rise without tears, and causing the coagulation of the starch at the surface of the bread, resulting in a shinier look and a longer shelf-life. The steam system in this oven is designed with extreme efficiency and efficacy, creating instantaneous steam in large quantities, and evenly distributed in each baking chamber. In fact, even if you need to bake fast successive loads of products requiring a short baking time and needing a lot of steam, this will not present a problem for the steam system in this oven. When steam is instantaneous and available in large quantities at any time, you can create bread that is more developed, shinier, and keeps its look and aroma longer. The Steam pipes are the real heart of this oven: the thermal “engine” that carries the heat to the baked products. They are what create powerful and uniform heating throughout the oven at a low cost. The steam pipes create a dense network of closed-circuit tubes in which steam circulates, wrapping around the baking chambers and radiating heat. The roof and the ceiling of each baking chamber are also heated by transversal pipes. Each tube constitutes a completely independent circuit and contains demineralized water that can become steam during heating. The tubes diffuse an absolutely uniform amount of heat in every part of the baking chamber. Created with absolutely brilliant engineering and know-how, the steam pipes dimension and diameter, their distance between each other, and the volume of water they carry, are all based on decades of experience and know-how. Each steam pipe is made of high endurance steel, cold-drawn, without welding, and they have a diameter of 28 mm and a thickness of 4 mm. They are certified and tested individually. Look how the Integrated loader on Bassanina deck oven works like a charm! Customizable Features:

The Perfect Steam at Your Fingertips

Why are Steam Pipes the Perfect Solution?

SEE THIS DECK OVEN IN A BAKERY

Weekdays: 8:30 - 5:00 PST

Weekends: Closed

EM Bakery Equipment USA Inc.

6731 Baymeadow Dr.

Glen Burnie, MD

21061

For Service/Support Contact:

Website by Virtual Roots & curious projects