Bassanina Steam Pipes Deck Oven ZOOM

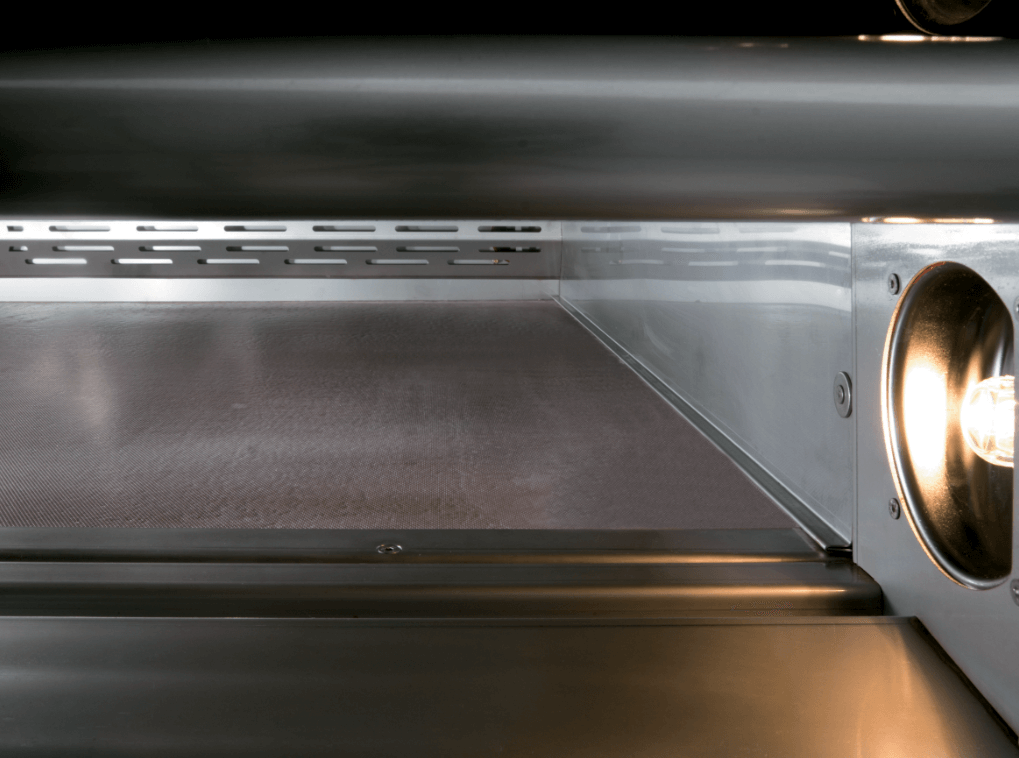

You can buy one of the most efficient, reliable, and powerful deck ovens to produce exceptional artisan products at high production levels. This oven is designed to offer versatility and heat flexibility, enabling rapid temperature adjustment and allowing you to bake your best of different types of products (bread, cakes, pizza…). The oven comes with four overlapping baking chambers, each with independent high-yield steam control, lighting, and a high-performance, food-safe cement baking deck. First and foremost is its low-cost and extremely powerful heating system: a dense network of closed-circuit pipes in which steam circulates. This oven guarantees constant, optimal heat distribution and extraordinary temperature stability even while loading and unloading your product. The result is an exceptionally strong deep bake with excellent oven spring, healthy crust development and a longer shelf-life. Each deck is designed to work with a custom conveyor belt loader, allowing you to quickly load and unload baked goods with different models of loaders available. Each deck’s tempered crystal glass and steel doors are balanced for fast opening and closing. They can easily be removed for cleaning. Also, this Bassanina oven is one of the quietest ones available. The oven is made of stainless steel AISI 430 and AISI 304, with thicknesses of mm 1; 1,5, 2 or 3, depending on the parts. Unlike a large fixed brick and cement deck oven, this oven can be moved or repositioned without deconstructing the entire oven. Different sizes and models are available. The standard burner in this oven can be designed to accommodate diesel, propane, or natural gas.The Ideal Ratio between Capacity, Power, and Costs

Produce exceptional artisan products at high levels of production

An absolutely uniform amount of heat in every part of the baking chamber at a low cost to operate

Create your best bake: bread that is more developed, shinier, and keeps its look and aroma longer

The oven is designed, built and tested to perform continuous, uninterrupted baking cycles 24 hours a day

Stainless steel throughout, steam pipes without welding and individually inspected

Fuel Source: Gas, propane Electrical: 3-phase 208 V (compatible with 220 V) 60 Hz, 1-phase 208 V (compatible with 220 V) Optional Steam: Yes Baking surface: Stone hearth Baking area: 4 m2– 9 m2 depending on model Temperature range: Max 300°C (572°F) Even baking: Yes Air movement: Natural Convection Control panel: Electromechanical or digital panel Modularity: Yes Loader: Yes, integrated belt loader Maintenance: Low maintenance and easy oven cleaning features Safety: Safety thermostat, emergency button, steam exhaust, the temperature cool handle, auto shut off, barometric damper, heating changer

This oven allows you to control steam independently for each baking chamber. In baking, a large quantity of instant steam is needed to optimize the baking of the crust, which gives it a shiny crust, avoiding dehydration problems and bubbles formation. Steam is what maintains the dough’s skin elasticity, allowing the bread to rise without tears and causing the coagulation of the starch at the surface of the bread, resulting in a shinier look and a longer shelf-life. The steam system in this oven is designed with extreme efficiency and efficacy, creating instantaneous steam in large quantities and evenly distributed in each baking chamber. In fact, even if you need to bake fast successive loads of products requiring a short baking time and needing a lot of steam, this will not present a problem for the steam system in this oven. When steam is instantaneous and available in large quantities at any time, you can create more developed, shinier bread that keeps its look and aroma longer. The Steam pipes are the real heart of this oven: the thermal “engine” that carries the heat to the baked products. They are what create powerful and uniform heating throughout the oven at a low cost. The steam pipes create a dense network of closed-circuit tubes in which steam circulates, wrapping around the baking chambers and radiating heat. Transversal pipes also heat the roof and the ceiling of each baking chamber. Each tube is an independent circuit and contains demineralized water that can become steam during heating. The tubes diffuse an absolutely uniform amount of heat in every part of the baking chamber. Created with absolutely brilliant engineering and know-how, the steam pipe’s dimension and diameter, their distance between each other, and the volume of water they carry are all based on decades of experience and know-how. Each steam pipe is made of high-endurance steel, cold-drawn, without welding, and tested individually. Performance Take a look at our easy tutorial video, How to set up LCD Control Panel on Bassanina Zoom Ovens. Wanna go deeper? Take a look at How to Understand your Electric Components on Bassanina Zoom Deck Oven. The Perfect Steam at Your Fingertips

Why are Steam Pipes the Perfect Solution?

Troubleshooting? Want to learn more?

SEE THIS DECK OVEN IN A BAKERY