MONO Omega Confectionery Depositors

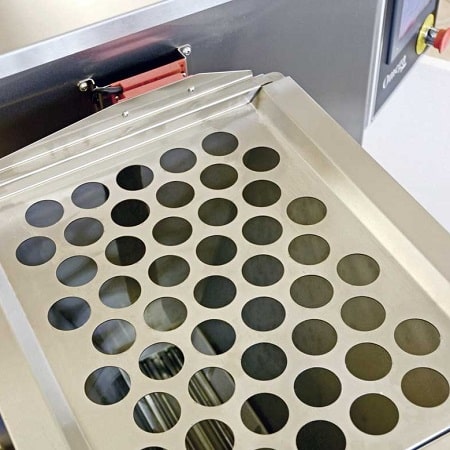

MONO Depositors are designed to produce a nearly endless array of products. Production is effortless and quick compared to time-consuming hand production. Constructed from hygienic and food-safe stainless steel. Designed for quick and easy cleaning and maintenance. For effortless positioning and moving is, the depositor equipped with castors. The breaks also provide full stability. Depositors are equipped with user-friendly, wide and color control panels, allowing you to save up to 650 programs. The menu includes icons for different shapes to ease control. The control panel can set up the deposits layout on the tray, as well as upward and downward movements and clockwise and anti-clockwise directions of the deposits. Deposits can be multi-layered. Trays can be inserted or taken out on the depositor’s left or right side. This MONO Depositor comes in three slightly different models: Omega Touch The essential model. Available with soft mix hopper in standard size. The Omega Plus Overall identical to the Omega Plus model but incorporates an enhanced motor. This upgrade allows using a wider range of mixes. This model can fit three different trays size- 400mm, 450mm and 600mm. Omega Plus with Wirecut The most advanced model. As the name said, this one is equipped with Wirecut with a safety guard. This allows for cutting hard dough, such as oatmeal dough or cookie dough. Can be equipped with two kinds of hoppers– Hard Mix Hopper as well as Soft Mix Hopper. Both hoppers can be in standard or extended size. As the previous one, this model can fit just two trays sizes- 400mm and 450mm, Looking for something small in matters of size and production? Then MONO Epsilon Confectionery Tabletop Depositors will be the right one.Your Personal Confectioner

MONO Depositor is bringing exceeptional efficiency, accuracy and consistency over 60 years

MONO Depositor is equipped with large colour touch screen with icons, can save up to 650 programs and can be set into 16 languages

And by that we mean very wide! Sponge Sheets, Swiss Roll, Angel Cake, Chocolate Brownies, Carrot Cake, Drops, Eclairs, Muffins, Meringues, Macarons and way more

Pour into hopper, close the lid and let the magic happens

All deposits will look identical as you have ultimate control over weight, size, height, length and shape

Customizable features:

Weekdays: 8:30 - 5:00 PST

Weekends: Closed

EM Bakery Equipment USA Inc.

6731 Baymeadow Dr.

Glen Burnie, MD

21061

For Service/Support Contact:

Website by Virtual Roots & curious projects