Vitella Automatic Dough Divider Rounder

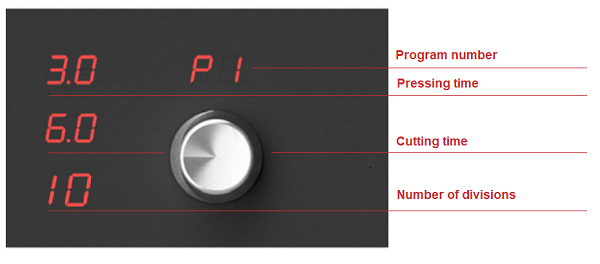

This fully automatic divider rounder is a reliable machine for automatic dough cutting and shaping. It has been designed to work effortlessly and efficiently without compromising quality. Hydraulic handling machine, with two cylinders for the pressing phase and one cylinder for cutting. The dough hydration this divider rounder is able to handle is up to 65%. The control panel allows saving up to 9 programs. The saving process is done in a few seconds. The divider rounder has a special button for adjusting the pressing time and the size of the chambers. Constructions and knives are made of stainless steel, guaranteeing a long life cycle. The basins are aluminum, with anticorrosive surface treatment. The machine is equipped with wheels for easy manipulation and stabilizing legs for safe anchoring. Maintenance of this machine is very easy as the divider rounder contains a button for knife cleaning. Divider rounder is focusing on safety features like a switch for the automatic stoppage with the front panel open or with an open cover and more. The machine is shipped with three food-safe plates.Absolute Bun Preciseness

Great features bring excellent results

Allows you to save ten programs

Uses an oscillating plate to shape each piece of dough into a bun of the perfect weight

Easily process different kinds of dough

The machine has a button for cleaning the knives and easy-to-clean components

Electrical: 3-phase 220 V Total Power: 1.5 kW Shipping Weight: 279 kg (615 lb) Number of Divisions: 11-52, depending on model Weight Range: 0.18-0.5 kg, depending on model Programs: Save up to 10 programs Production Range: 1300-6200 per hour, depending on model Maintenance: Recommended periodic cleaning inside and outside Safety: Emergency button, latch handle

Still browsing? If you feel more like DIY check Vitella manual divider rounder, no automation, using just a pure humankind workforce. If you wanna go halfway, Vitella semi-automatic divider rounder will be the right one. Combination of automatic pressing and manual rounding.

Weekdays: 8:30 - 5:00 PST

Weekends: Closed

EM Bakery Equipment USA Inc.

6731 Baymeadow Dr.

Glen Burnie, MD

21061

For Service/Support Contact:

Website by Virtual Roots & curious projects